Carbon Steel Casting- Unlocking the Potential of Customized & Versatile Tooling

As the leading investment casting supplier, Lida is very capable of making carbon steel castings in all carbon steel alloys, especially low carbon casting and high carbon casting.

Carbon steel is among one of main materials in the world of steel castings. Carbon steels can be classified into below types according to their carbon content:

Low-carbon steels (< 0.20% C): Offer a range of tensile properties via heat treatment and can be hardened to give high surface hardness with abrasion resistance and good core ductility.

Medium-carbon steels (0.20 to 0.50% C): This composition allows it to be more durable, pliable, and stronger. A range of tensile strengths are possible with good ductility and shock resistance, readily machined in the softened condition.

High-carbon steels (> 0.50% C): Strong and has a good shape memory, making it a particularly useful option for spring manufacturers. This alloy steel for high tensile applications is subject to wear and abrasion and is suitable for heavy-duty applications as well.

Carbon Steel Castings Process

Same as alloy steel casting and stainless steel casting process, carbon steel casting could be produced in two kinds of different casting processes: Water Glass Casting and Silica Sol Casting. Water Glass Casting: This type of casting process can make carbon steel castings with tolerance CT7-CT8. Most of carbon steel castings use water glass casting process for its low cost. In China, around 70% casting foundries are water glass casting manufacturers. Silica Sol Casting: Another lost wax casting method for carbon steel casting. This casting process can control carbon steel castings within tolerance CT5-6. Also the surface finish will be much better. The only consideration of selecting this process is its high production cost. If you have high demands on your carbon steel castings, we recommend this process.

Benefits of Carbon Steel Castings

Carbon steel is an extremely popular material option for steel castings, as it has a vast range of applications in several different industries. For the low material cost and a variety of material grades, carbon steel casting is commonly used and can improve its strength, ductility and other performance by heat treatment for industrial applications. Due to its ferromagnetic properties, this material is particularly useful for motor and electrical appliances. Carbon steel is safe and durable and has a high level of structural integrity, features that add to its popularity and make it one of the most created alloys in the world.

Carbon Steel Castings Manufacturer & Exporter

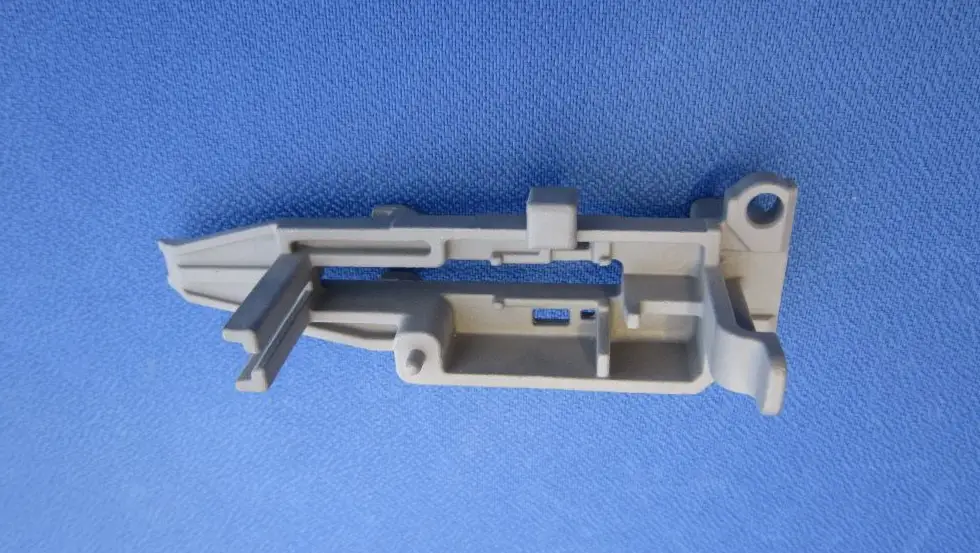

As the leading investment casting supplier, Lida is very capable of pouring carbon steel castings in all carbon steel alloys, especially low carbon casting and high carbon casting. Common used material grades of carbon steel castings in our company are AISI 1010, AISI 1020, AISI 1035, AISI 1045, AISI 1060, etc. Besides, we can also customize such carbon steel casting according to your material compositions. Our investment casting capabilities enable us to achieve tight tolerances in different dimensions for your cost savings.

We also have other capabilities of secondary operations such as machining, non-destructive testing, heat treat, and assembly as we are equiped with a complete set of testing instruments like 2-Dimensional, 3-Dimensional, Projector, metallographic analyzers and X-Ray, etc to ensure parts quality and dimensions compliance. Like alloy steel castings & stainless steel castings, We can prove to supply carbon steel castings as good as any foundry can offer, better than most.

Please contact us and let us know how we can serve your carbon steel investment casting needs. If you are still confused at the grade of your castings, no worries, our material expert will advise the right option for you. Please consult us to assit on your metal customizing project now!