Durable, Versatile, and Tailored: Why Custom Stainless Steel Casting is the Idea

What is Custom Stainless Steel Casting?

Custom Stainless steel casting is a metal working process to produce custom stainless steel parts. As a mostly often used casting metal process, it works by pouring melton stainless steel into molds for solidification, thus to achieve a solid stainless steel component in a desired shape.

By using lost wax casting process, it can produce stainless steel castings with intricate structures and smooth finish which can save considerable post machining cost.

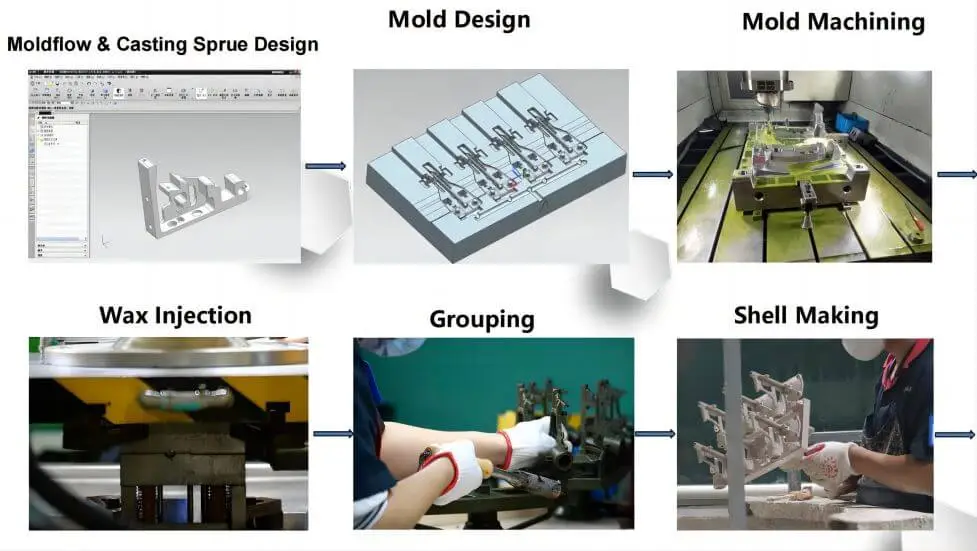

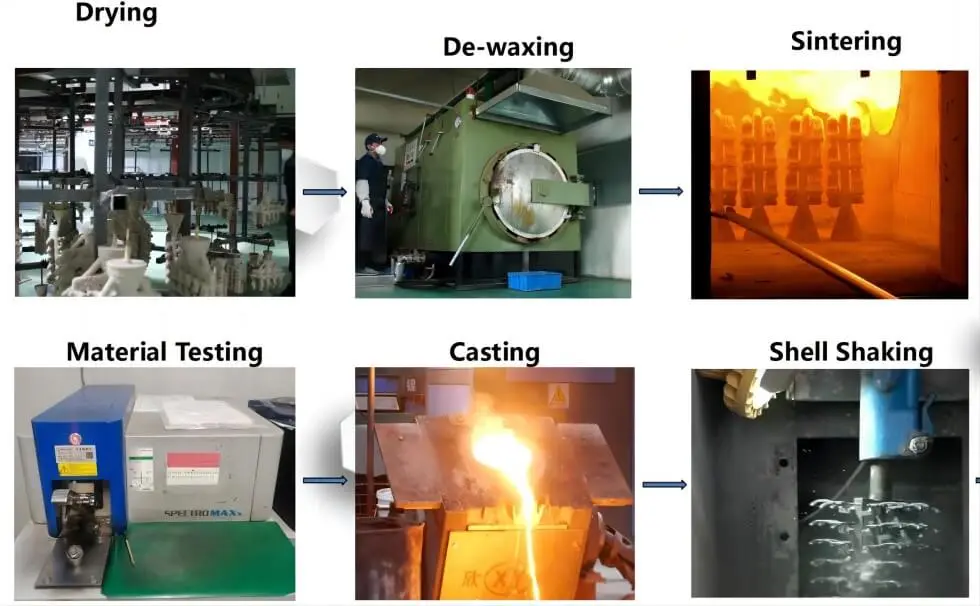

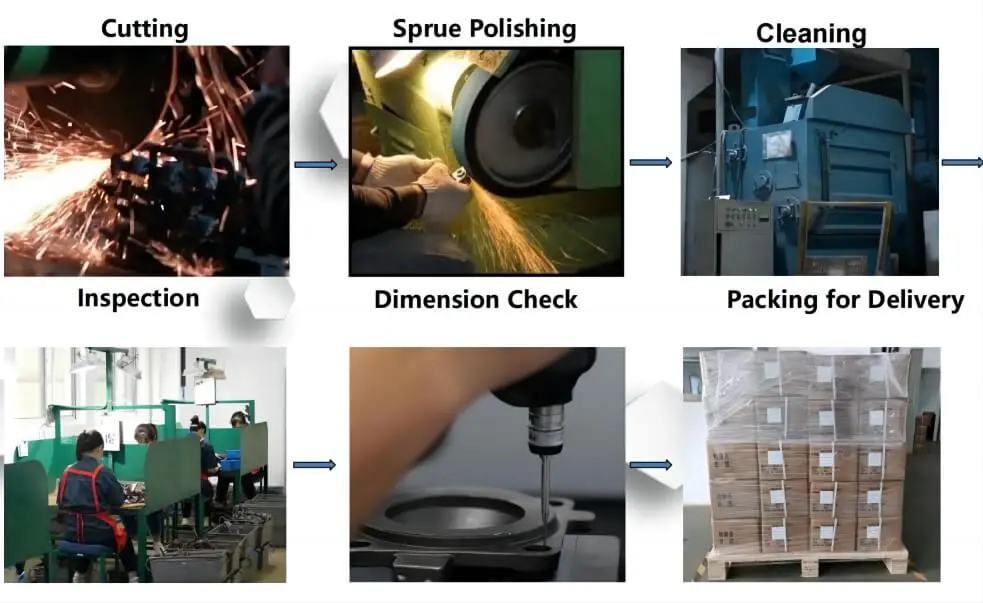

Process of Custom Stainless Steel Casting

Same as alloy steel casting and carbon steel casting, stainless steel casting process is a metal forming process of lost wax casting involving the forming of a wax pattern, which is then coated by refractory ceramic shell to form a shell mold. When the wax inside the shell mold is melted out, leaving the ceramic shell as a mold. Molten stainless steel in fluid is then poured into the mold to form a casting component. After the metal solidifies and the mold is removed, Lida can offer near-net shape of stainless steel casting parts without secondary machining process while some investment castings may require a secondary machining process.

Advantages of Custom Stainless Steel Casting

- High resistant to corrosion. High strength, high quality surface finish, also have no parting lines, further enhancing part aesthetics.

- High dimensional accuracy &Complex near-net shape-- It is a near-net shape casting process with minimal finishing tolerances. After finishing, parts have an impressive dimensional tolerance of +/- 0.075 mm.

- High efficiency&Affordable.

- Endlessly recyclable.

- High durable.

- Large Parts-This method is capable of dealing with different part sizes. It is suitable for parts as lightweight as 100g and as heavy as 300KGS. It produces huge turbine blades of the same quality as minute medical equipment.

Applications of Custom Stainless Steel Casting

With its exceptional durability, versatility, and tailored production, this process offers unmatched benefits for a wide range of industries. Whether you're manufacturing complex parts for the aerospace industry or creating precision components for medical devices, custom stainless steel casting delivers exceptional performance and reliability. By leveraging advanced technology and expertise, Lida stainless steel casting allows for the creation of intricate and precise designs that other casting methods may struggle to achieve.

- Medical devices

- Mining Industry

- Petrochemical Industry

- agriculture/food

- Aerospace

- New Energy

- Automotive Industry

- Military

- Firearms

- Machine Tools

Key Considerations for Selecting a Professional Stainless Steel Casting Provider

One of the first things to consider when selecting a custom stainless steel casting provider is their expertise and experience in the industry. Look for a company that has a proven track record of delivering high-quality castings. A provider with extensive experience in stainless steel casting will have the knowledge and skills necessary to produce precision parts that meet your exact specifications.

Additionally, consider the industries that the casting provider has worked with in the past. If they have experience in your specific industry, they will have a better understanding of the unique requirements and challenges that come with it. This industry-specific expertise can make a significant difference in the quality and performance of the final product.

What Types of Casting Metals are Used for Custom Stainless Steel Casting in Lida?

Stainless steel is one of the common casting metals for industrial and commercial castings because it offers superior mechanical properties and corrosion resistance, making it long-lasting in severe environments.

The most frequently used cast stainless steel grades Lida is capable of for stainless steel castings are: 304 stainless steel casting, 304L Stainless steel casting, 316 Stainless Steel Casting, 316L, 17-4Pph Investment Casting, 302, 303, 310, 321, 347, and 410. This casting type is the most common for over 70% of production. Grade 304 is the most generally specified casting grade, with different austenitic grades such as 316 and 317.

| Material Grade | General Use | Applications |

|

300 Series Stainless Steel (ANSI) |

303 (CF165) 304 (CF8) 304L (CF3) 309 (CH20) 310 (CK20) 316 (CF8M) 316L(CF3M) |

|

|

400 Series Stainless Steel (ANSI) |

410 (CA15) 416 (IC 416) 420 (CA40) 431 (IC 431) 440A (IC 440A) 440C (IC 440C) |

|

|

17-4 PH Series |

|

|

Top Custom Stainless Steel Casting Company in China

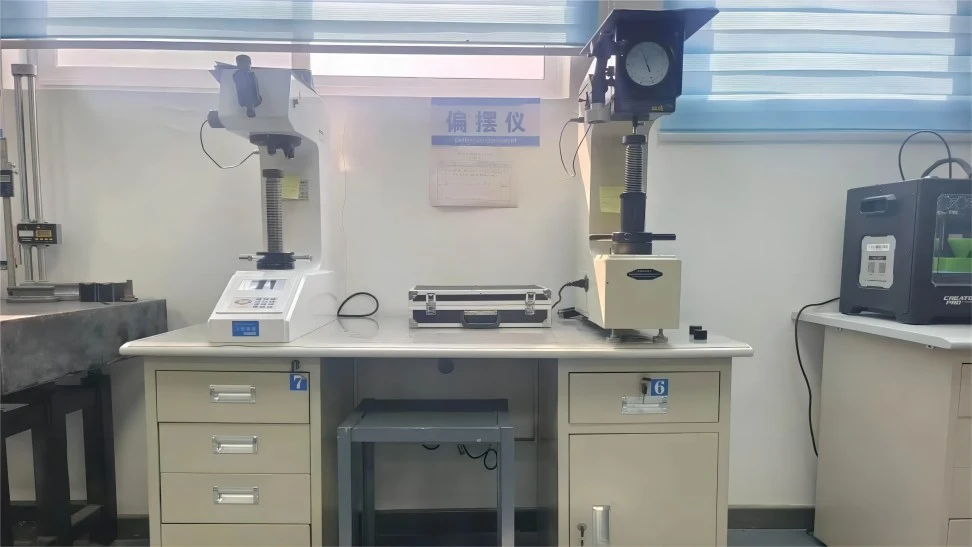

Lida Stainless Casting Foundry is one of the leading precision investment casting manufacturers in China. We can manufacture custom stainless steel investment castings that match your exact design specifications with the expertise of our engineering team and cutting-edge QC inspection devices. For precision cast parts ranging from 50g to 300kg, we provide tight tolerances and consistent part to part repeatability.

Lida stainless steel casting process also offers greater flexibility in terms of size, shape, and design, ensuring that your product can be tailor-made to your exact specifications. Additionally, stainless steel's corrosion resistance and high temperature and pressure capabilities make it an ideal material for various applications. From automotive parts to architectural components, this versatile metal can withstand harsh environments while maintaining its integrity. With its unmatched durability, versatility, and tailored production capabilities, custom stainless steel casting is the ideal solution for manufacturers seeking precision and longevity in their products. Whether you're looking to optimize performance or expand your product's lifespan, this innovative casting process is the key to success.

Lida has extensive experience producing stainless steel investment castings from various alloys to get you the desired stainless steel casting parts with excellent corrosion resistance, mechanical properties, and part dimensional geometries that perform best in your application. Contact Lida for your stainless steel casting project, we can help you find the right alloy to fit your stainless steel casting requirements using our on-site spectrometer. This device gives you the ability to produce your own “specialty alloy” and enables you to change the chemistry to fit your application environment. In addition, more testing devices on-site to ensure your part quality and precision.

Stainless Steel Casting Capabilities of Lida Green Energy:

-

Complicated, near-net shape parts without secondary machining

-

Own part assembly capabilities, can easily convert multiple parts into single assemblies

-

Thin walls for weight reduction opportunities

-

Surface finish of Ra6.3 or even better

-

Linear tolerances within CT4-CT6

-

Highly complex dimensional geometry

-

High precision machinability, we have 7 cutting edge CNC machines which can process machining in house.

-

Can produce high alloy steel parts like nickel based alloy and cobalt based alloy parts by using vacuum melting furnace.

Certificates of Lida Green Energy

Lida Green Energy adheres to various quality standards. Our IATF 16949:2016 certificationsuggests our commitment towards high quality standards.

Our extensive casting experience and mature casting technique makes us the most reliable one-stop source for stainless steel castings. The competitive prices and full services of stainless steel castings are the most attractive factor for clients from USA, UK, Canada, Australia, Japan and South Korea, etc to purchase products from our company in China.

Check out how Lida using the investment casting process to produce various high precision cast parts with intricate shapes like turbine blades, medical equipment, oil field equipment parts, firearm components, jewelry, golf club heads, gears, pulleys, valve &pump components, machinery parts, doorknobs, auto parts and components, airplane parts, kitchenware, utensils, cookware, construction hardware, gearbox cases, food processor, automotive cylinder heads, cylinder boxes, pipes, tubes, assemblies, plus many other machine components — anything with complex geometry benefits from this technology.

Need stainless steel casting service in China? Contact us now!