Strict Quality Control Scheme

Lida takes quality as the first priority in our foundry since establishment, we control quality from the metal composition to finished parts to ensure part dimension geometries and compliance. We have introduced a full set of professional inspection and testing instrument and have trained a team of QC expertise to take good care of each part delivered to each client. We have received sound reputation and good satisfaction from our customers.

1) Lida has fostered an experienced QC team with 15 QC personnel to ensure that products are satisfactorily delivered to customers from raw materials to finished products. Each batch of pouring should be tested by our German spectro spectrum analyzer to make sure each chemical component is consistant to related standards, and ensure that every shipment is delivered with high-quality products. The factory requires that the high-quality product rate must be above 95%. We are constantly learning and researching to improve the qualification rate of products and explore new heights of technology.

2) Lida has established a scientific and strict quality control system and passed the TS16949 and ISO14001, ISO45001 certifications, which enables us to implement the standard production process, and care for the environment and our employee's occupational health.

Depending on regulatory or specific customer requirements, the appropriate inspection and testing methods that can be utilized by our foundry include, but are not limited to:

- Visual Inspection

- Dimensional: from first principles to CMM, including ability to tolerance from CAD data

- Chemical analysis: the use of mass spectrometry in the analysis of incoming raw metals for verification and at post cast is standard at Lida

- Microstructural analysis

- Full traceability: from raw material to final product

- Die penetrant inspection

- Mechanical testing

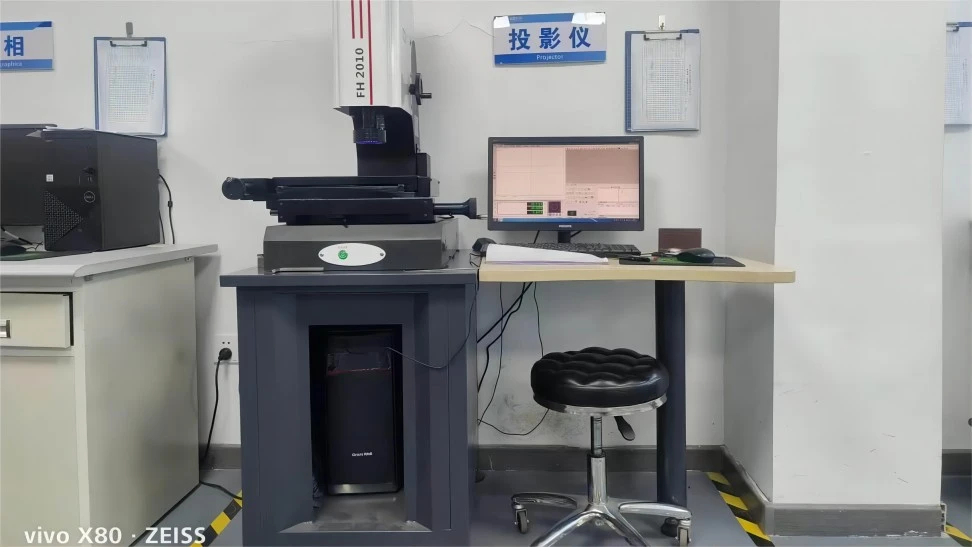

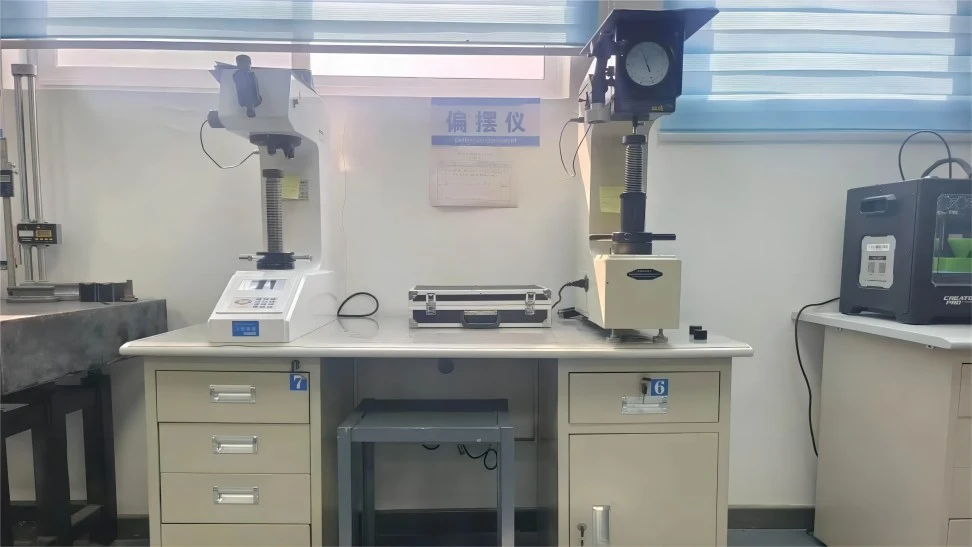

3) The foundry has complete full set of inspection equipment, including projectors, 3D measuring machines, metallographic analyzers, to maintain the most stringent standards and premium quality.

Polishing Machine

3-Dimensional

Projector

Mable Platform

Deflection Instrument

Rockwell Hardness Tester

Metallographic