Production Capacity/Capability

Lida metal castings not only offer stainless steel castings, as one important part of our lost wax casting services, we also can process alloy steel castings. Lida has advanced vacuum melting furnaces, which can produce more than 98% high alloy steel castings, such as iron base, cobalt base, nickel base alloy, brass base alloy, etc. Product surface finish is smoother by this technology, no air vent and oxidization, and can resist high temperature, which can meet customer's requirements with higher standards. And it's widely used in aerospace and petrochemical industry such as the airplane engine part, engine impeller, turbine blade, reactor, heat exchanger, valves and pipes in petrochemical industry.

LE-TA Green Tech Capabilities Include:

-

The factory covers an area of 20,000 square meters, has 260 employees, and boasts a monthly production capacity of 150-200 tons.

-

The core technical team has extensive experience in mass production of precision casting products

-

The factory has a complete production chain enabling us to offer turn-key services for customers, including mold making, blank casting, heat treatment, machining, surface treatment, etc. to meet the various needs of customers

-

Can cast complicated, near-net shape parts in one piece to reduce or avoid secondary machining and welding cost and improve production efficiency

-

Own part assembly capabilities, can easily convert multiple parts into single assemblies

-

Thin walls for weight reduction opportunities

-

Surface finish of Ra3.2-6.3 or even better

-

Linear tolerances within CT3-CT6, minimal tolerance up to ±0.05mm

-

Exquisite patterns and text can be directly casted on part surface to save post machining costs for customers.

-

Highly complex dimensional geometry

-

High precision machinability, tolerances down to ±0.0004″ (±0.01mm) by equipped with 29 sets cutting edge machining equipment which enables us to process machining in house thus reduce leadtime and control quality.

-

Can produce high alloy steel parts like nickel based alloy and cobalt based alloy parts by using vacuum melting furnace.

More technical questions please contact us if you have such a need.

Lida has the ability to cast complex parts, with the help of advanced casting simulation software to assist product process design, the use of melt core, ceramic core, salt core and other special processes to achieve complex parts manufacturing.

Lida has the ability to cast complex parts, with the help of advanced casting simulation software to assist product process design, the use of melt core, ceramic core, salt core and other special processes to achieve complex parts manufacturing.

We can offer multiple casting solutions for customers with specific requirements, and recommend the best suitable solutions for them to optimize parts functions and control cost within budget, including carbon steel castings, stainless steel castings, alloy steel castings, tool steel castings.

And have rapid production capacity for all kinds of castings, which are used in oil field equipment, pneumatic tool accessories, power tool accessories, automotive, shipbuilding, construction, aviation, hardware and other industry tools, construction machinery, pump valves, etc. We are equipped with a full set of cutting-edge and efficient machines, including:

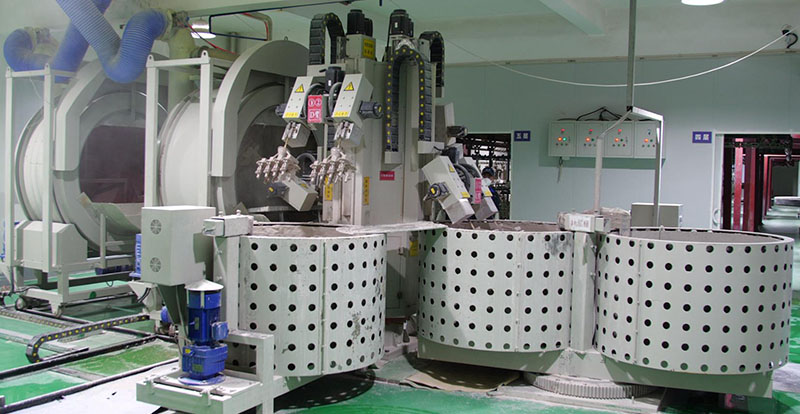

| Wax injection machine | Wax Treatment System | Four-arm shell robot |

Vacuum melting furnace |

Shot blasting machine | Sintering furnace | Driller | Centerless grinding | Machining Equipment | |

| set | 8 | 1 | 1 | 1 | 6 | 8 | 6 | 1 | 29 |

| capacity | 70% | 80% | 60% | 75% | 75% | 75% | 65% | 70% | 70% |