What is 316 Stainless Steel Casting &Their Remarkable Advantages and Applications

Stainless steel is a versatile material that has revolutionized many industries. It is lightweight, durable and resistant to corrosion, making it a top choice for construction, manufacturing and even jewelry making in stainless steel casting foundries. Among the different types of stainless steel casting available in the market today is 316 stainless steel casting. This type of stainless steel has unique properties that make it stand out from other alloys. In this blog post, we'll explore what makes 316 stainless steel casting so special while highlighting its pros and cons and how to properly care for it.

What is 316 Stainless Steel Casting?

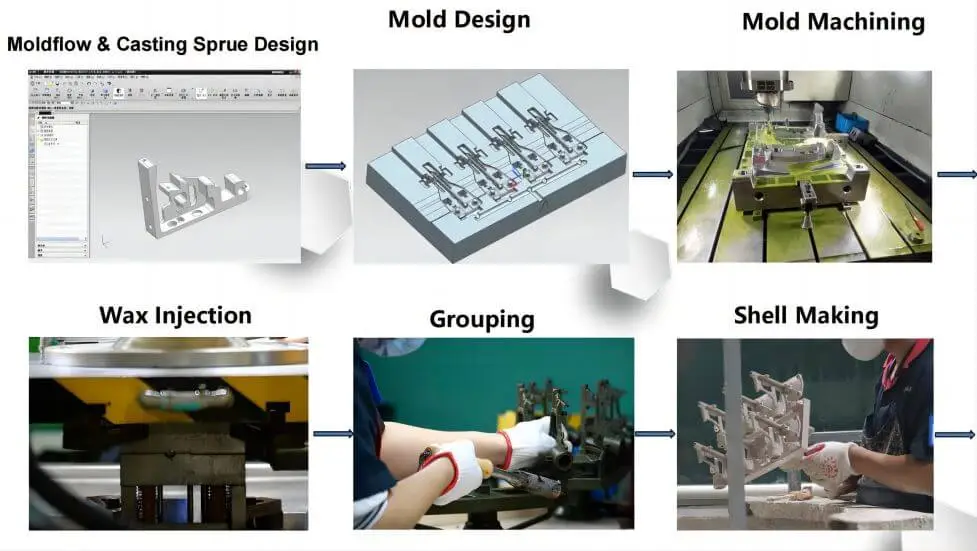

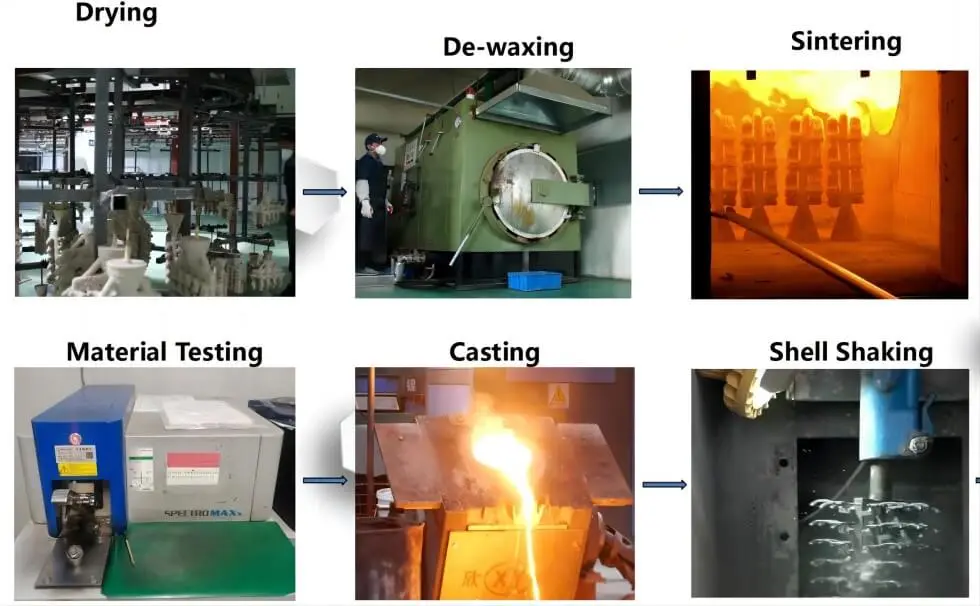

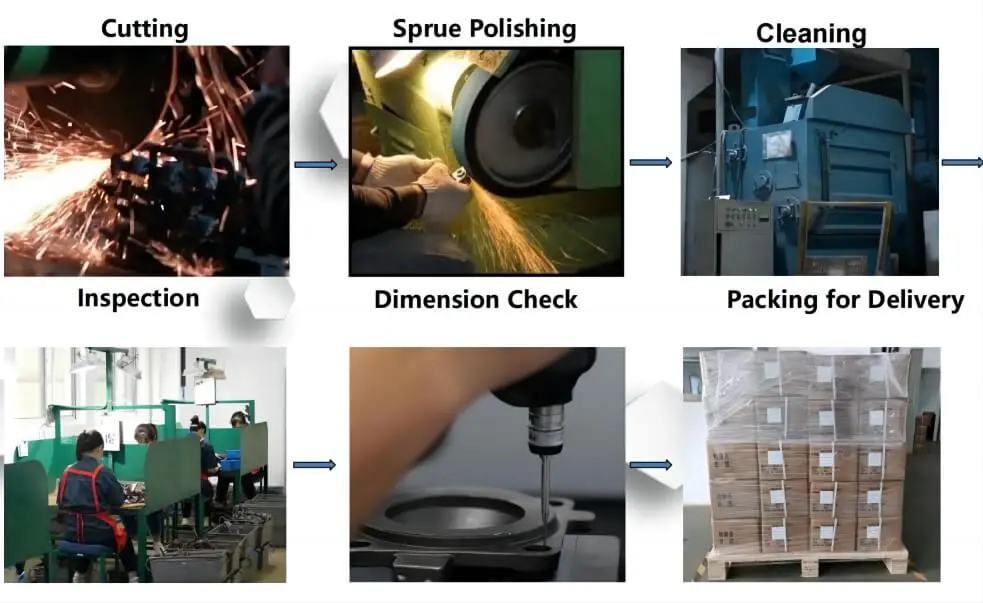

316 stainless steel casting is a metal forming process of lost wax casting involving the forming of a wax pattern, which is then coated by refractory ceramic shell to form a shell mold. When the wax inside the shell mold is melted out, leaving the ceramic shell as a mold. Molten stainless steel in fluid is then poured into the mold to form a casting component.316 stainless steel is an austenitic stainless steel containing molybdenum. It is considered an upgrade from the more common 304 stainless steel due to its enhanced corrosion resistance, making it ideal for use in harsh environments such as marine applications.

Properties of 316 Stainless Steel Casting

This alloy has less carbon than 304, which makes it less susceptible to sensitization—a process that can lead to intergranular corrosion. This property makes it suitable for welding and other high temperature applications.

In addition, 316 stainless steel casting has excellent strength and toughness at both high and low temperatures, making it versatile and used in industries ranging from medical device manufacturing to food processing plants.

In terms of appearance, 316 stainless steel casting has been polished and exudes an attractive metallic luster. Its aesthetic appeal coupled with durability make it popular with jewelry designers who want their pieces to withstand daily wear and tear while retaining their luster.

All in all, 316 stainless steel is a special alloy that due to its unique properties makes it ideal for different industrial applications where corrosion resistance is crucial.

Different Types of Casting Materials for 316 Stainless Steel Casting

316 stainless steel is a popular material choice for a variety of applications in investment casting industry due to its excellent corrosion resistance, strength, and durability. However, it is important to note that there are different types of 316 stainless steel on the market.

One is standard 316 stainless steel with molybdenum. This alloy provides excellent corrosion resistance in harsh environments such as marine or chemical exposure.

Another type is low-carbon 316L stainless steel, which has even less carbon than standard 316. This makes it ideal for welding applications where maintaining corrosion resistance after welding is critical.

There is also high-performance 316H stainless steel with a higher carbon content than standard 316. This results in increased tensile strength and yield strength at elevated temperatures, making it suitable for high-temperature applications such as heat exchangers or furnace components.

Duplex grade 2205 combines the advantages of austenitic and ferritic grades to provide increased strength and toughness while still maintaining good corrosion resistance.

Understanding the different types of 316 stainless steel can help you choose the one that best suits your specific application needs.

Advantages and Applications of 316 Stainless Steel Casting

316 stainless steel is a widely used material in various industries for steel casting foundries, due to its many advantages. One of the most significant advantages of 316 stainless steel casting is its corrosion resistance, making it ideal for use in harsh environments such as marine applications and chemical processing plants.

Another benefit of 316 stainless steel casting is its exceptional strength and durability. This type of metal can withstand high temperatures, extreme pressures, and heavy loads without compromising its structural integrity. Additionally, its low carbon content makes it more ductile than other types of stainless steel casting materials.

Additionally, 316 stainless steel has excellent weldability, making it easy to machine into the different shapes and sizes required for specific applications. It also maintains its appearance over time thanks to its excellent antioxidant and stain resistance.

Finally, 316 stainless steel is an environmentally friendly option because it is recyclable; this means scrap or end-of-life products from the manufacturing process made with this alloy will be melted down into new metal sheets or rods rather than directly deal with.

All in all, there are many benefits to using 316 stainless steel casting, making it highly sought after in various industries around the world.

Lida has extensive casting experience in manufacturing 316 stainless steel casting parts and other casting materials, contact us if you have such needs.