What is Investment Casting Process and How Does Investment Casting Work?

What is investment casting Process?

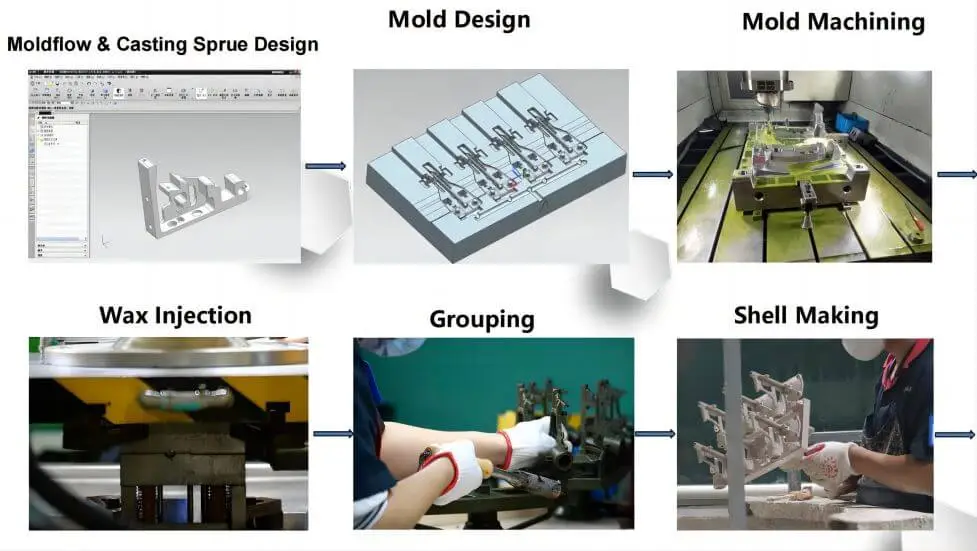

Investment casting, also known as precision casting or lost-wax casting, is a manufacturing process of metal parts in which a wax pattern is generated to shape a disposable shell mold. A wax pattern is made in the exact shape of the item to be casted. Then the wax patterns are grouped into a "lost wax casting tree". After drying, the lost wax casting tree is dipped into a slurry made of refractory ceramic material. Once the ceramic material is hardened, it is turned upside-down and heated until the wax melts and drains out. The hardened ceramic shell becomes an expendable investment mold. Molten metal is poured into the shell mold and is left to cool down. The metal casting piece is then broken from of the spent mold.

The term investment casting is derived from the process of “investing” (surrounding) a pattern with refractory materials. Investment casting is often selected over other molding methods because the casting pieces resulted from the investment casting process present fine detail and excellent as-cast surface finishes. They can also be cast with thin walls, tight tolerance and intricate internal structures. Compared to sand casting, investment casting does not require a draft and more cost effective.

These process qualities can provide net shape or near-net shape castings, which enables customers to save significant cost in material, labor, and post machining. It can make casting parts of most common metals, including aluminum, bronze, magnesium, carbon steel, and stainless steel. While we Lida Green Energy is capable of making carbon steel casting, stainless steel casting and various high alloy casting parts. Parts manufactured with investment casting include turbine blades, medical equipment, firearm components, gears, automotive parts, jewelry, construction hardware parts, and many other machinery parts with complicated geometry.

If you have such casting needs, please don't hesitate to contact us now to consult on your specific custom metal part.

How investment casting works/The Investment Casting Process

The investment casting process is composed of several steps: metal die building, wax pattern generation, wax pattern tree assembly, slurry dipping, dewaxing, ceramic shell making, pouring, cooling and solidification, shakeout of the ceramic shell, cleanup and post machining if necessary.

With over a decade of experience in lost wax casting manufacturing, Lida is truly a metal expertise. Inquire to us on any of your metal casting concerns, we are always here to help.