Investment Casting Tolerance

Investment Casting Tolerance means the dimension range that can be achieved by investment casting process. While lost wax casting tolerance as one of investment casting process, it may be affected by a number of factors. Such as mold temperature, wax temperature, wax injection pressure, mold or shell composition, furnance temperature, rate of cooling, position of the wax pattern on the “wax tree”, part sprue position and heat treat temperature all bear directly on tolerances required in the lost wax casting industry. Althought there is a tolerance standard in lost wax casting industry, it may still different from foundry to foundry, as some foundry may be capable of processing thin wall small parts, and others could be more professional in larger casting parts.

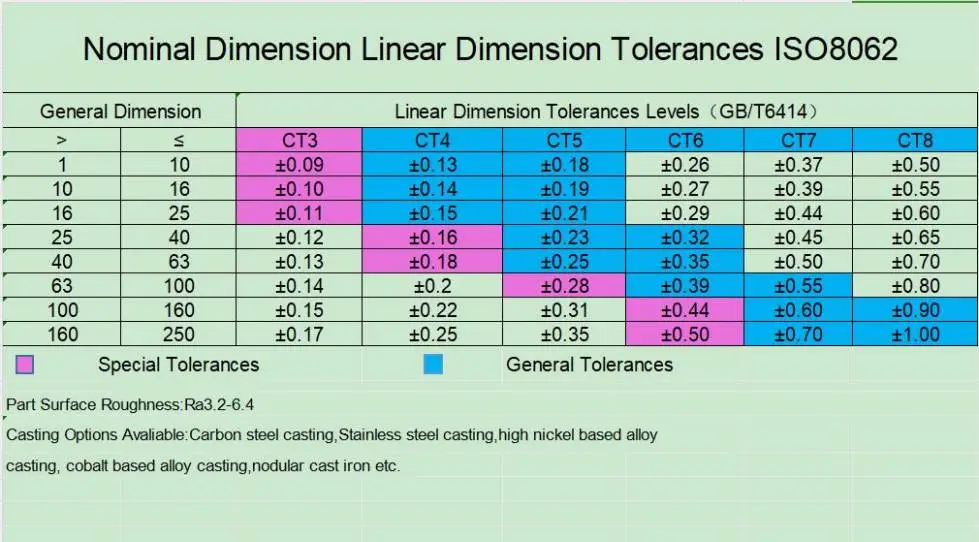

Generally, we can divide it into Linear Tolerances and Geometric Tolerances.

Linear Tolerances

Linear tolerancing is normally applied to the following features of investment castings: Length, Concentricity, Fillet radii, Holes, Flatness, Straightness, Corner Radii, and Curved Holes. And the linear tolerances of each casting process are not the same. For example, water glass lost wax casting can control general linear tolerances between CT7-CT8, and lost foam casting can meet CT8-CT9, while the tolerances of silica sol casting is the most precise, it is CT5-CT6. Below is a list of tolerance standard for casting ISO 8062 that Lida complies with:

Lost Wax Casting Tolerances in Lida Steel Foundry

With 15 years dealing with lost wax casting manufacturing and introduction of advanced testing instrument and CNC machines, Lida Steel Foundry can offer lost wax casting parts with extremely tight tolerances, and confirm each provided casted parts within allowed tolerance ranges. We are always follow rigid tolerance standards so that all steel castings from our foundry are accurate and try our best to avoid or reduce further machining, thus to save unnecessary costs for our customers. Our corporate principle is to deliver high quality steel castings with ultimate accurate dimensions.

If your required tolerances are not achieved after casting, don't worry, our machining capability will help to meet the required effect, we have strong machining capabilities with in-house CNC machines and engineers with rich experience. Contact Lida lost wax casting foundry, our metal expert will discuss in details about the tolerance issue for your part.