How Are Vent Holes Caused in Precision Castings and How to Solve It?

How Are Vent Holes Caused in Precision Castings and How to Solve It?

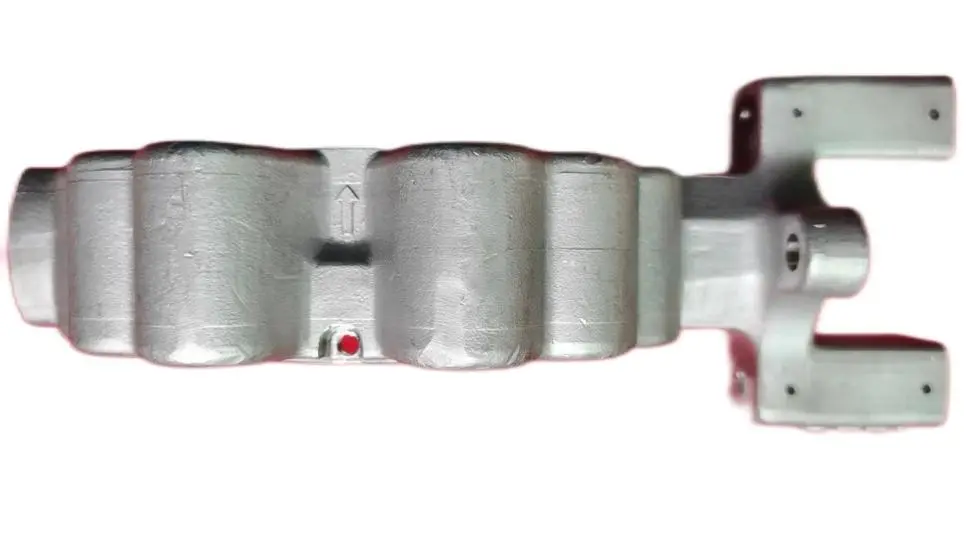

Vent holes are one of the more common defects in precision castings. vent holes refer to the defects of smooth and flat holes in individual positions of precision castings. vent holes are generally not found until after machining. Based on decades of years experience in precision castings manufacturing, Lida precision casting foundry has summarized the subjective reasons and prevention methods of porosity in precision castings as follows:

Subjective Reasons of Vent Holes Caused in Precision Castings:

In most cases, the vent holes are mainly due to the insufficient roasting of the precision casting shell. When pouring molten steel, a large amount of gas will be generated in the shell instantly and cannot be discharged smoothly, thus invading into the molten metal to form vent holes; In addition, due to the subjective reasons of the shell-making process or the shell material, the air permeability of the shell is too poor, the gas in the cavity is difficult to discharge, and it enters the molten metal to form vent holes; Furthermore, the air involved in the molten steel which can not be discharged during pouring. Casting porosity.

Prevention Methods

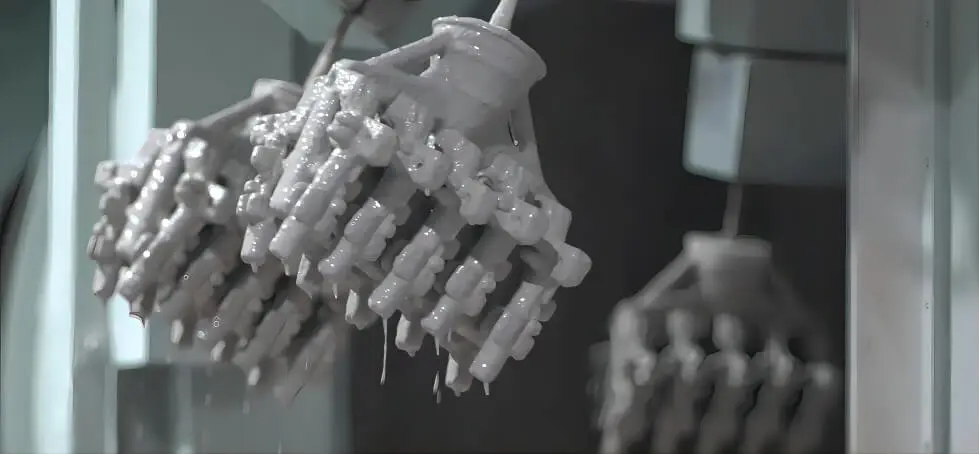

When precision castings conditions permit, set vent holes at the highest point of castings with complex structures. Besides, when designing the gating system, fully consider the exhaust requirements of the shell. The shell roasting temperature and cycle should be reasonable, and the heat preservation cycle should be sufficient; When de-waxing, the wax should be completely removed. And should properly reduce the distance from the ladle nozzle to the sprue cup, and the pouring speed should be uniform to ensure that the molten steel fills the cavity smoothly, and the air in the molten steel should be as little as possible, so that the gas in the cavity and molten steel can be discharged smoothly.

Our Design & Production Capabilities Include:

-

Complicated, near-net shape parts without secondary machining

-

Own part assembly capabilities, can easily convert multiple parts into single assemblies

-

Thin walls for weight reduction opportunities

-

Surface finish of Ra6.3 or even better

-

Linear tolerances within CT4-CT6

-

Highly complex dimensional geometry

-

High precision machinability, we have 7 cutting edge CNC machines which can process machining in house.

-

Can produce high alloy steel parts like nickel based alloy and cobalt based alloy parts by using vacuum melting furnace.

Top Precision Castings Foundry in China

Lida Precision Casting Foundry is one of the leading stainless steel precision investment casting companies in China. We can manufacture custom stainless steel investment castings that match your exact design specifications with the expertise of our engineering team and cutting-edge QC inspection instruments. For parts ranging from 50g to 300kg, we provide tight tolerances and consistent part to part repeatability. Contact our metal expert today to check out what we can bring for you.