How Precision Casting Technology is Used for Automobile Manufacturing?

In automobile manufacturing, it is inevitable to use various accessories, and the quality of these accessories directly affects the performance and life of the automobile. And precision casting technology is a technology that can manufacture high-quality auto parts. Let's explore which auto parts are made by precision casting.

Engine Parts for Car by Precision Casting

The engine is the key component of the car, and its quality directly affects the performance and life of the car. Many parts in automobile engines need to be manufactured by precision casting. For example, cylinder heads, crankshafts, intake manifolds, exhaust pipes, etc. all need to be completed with precision casting technology to ensure the stability and reliability of engine performance.

Body Shell By Precision Casting

The body shell is also one of the auto parts that require precision casting. For example, the wheels of automobiles need to be manufactured using aluminum alloy precision casting technology to ensure their strength and light weight. In addition, some important parts in the body, such as the bracket of the suspension system, also need to be manufactured by precision casting technology.

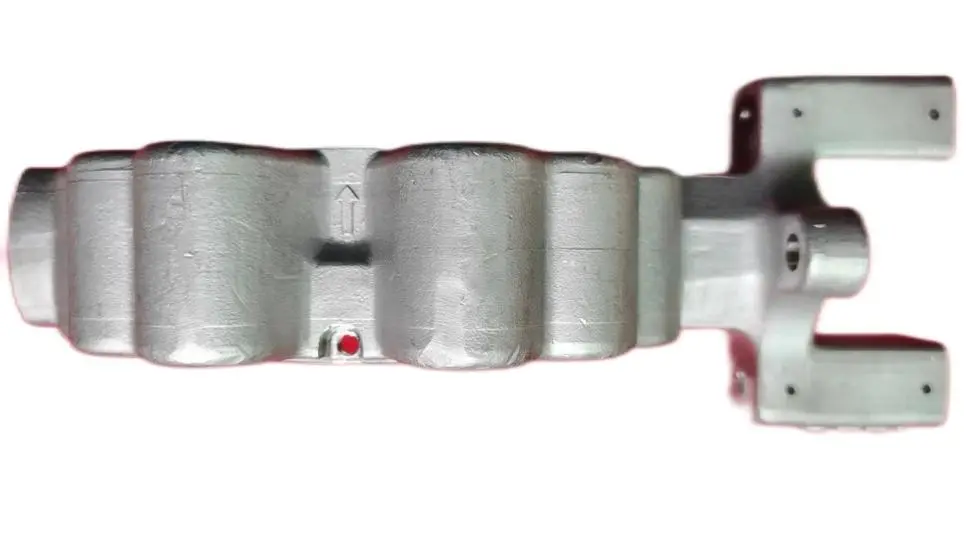

Brake System by Precision Casting

Thirdly, the brake system is also one of the important parts of the car that needs to be manufactured using precision casting technology. Brake calipers, brake discs and other components in the automotive braking system require the support of high-precision casting technology to ensure their accuracy and stability during braking.

Transmissions and Steering Systems by Precision Casting

In addition, components such as transmissions and steering systems also need to be manufactured using precision casting technology. In automobile manufacturing, since these components need to withstand harsh working environments such as overload and high-speed movement, high-quality materials and high-precision manufacturing processes are required to ensure their reliability and stability in long-term use.

Professional Precision Auto Part Supplier in China

Lida casting foundry manufactures various types of investment casting automotive parts, engine parts for car, which can improve the performance and life of the car. Connect to one of our engineers to consult in detail if you have such customizing needs for auto parts.

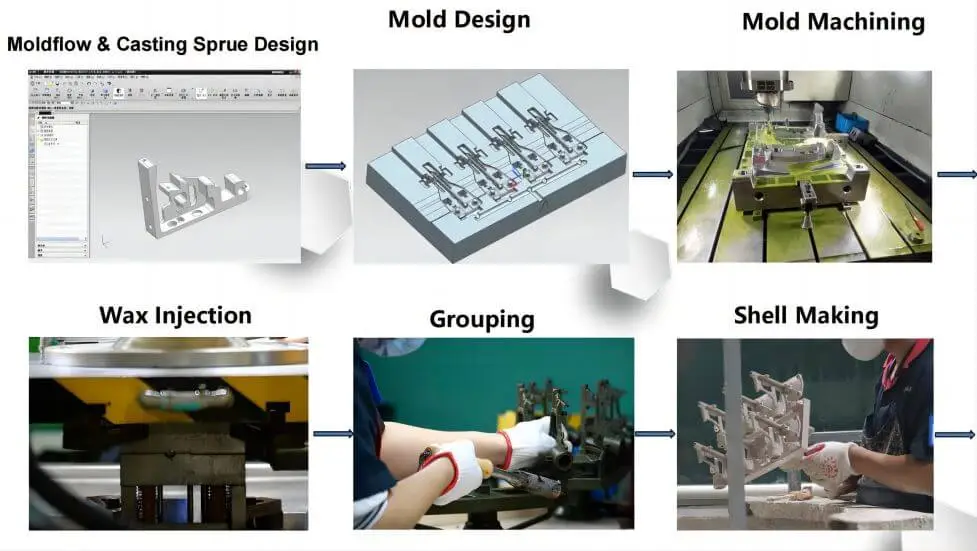

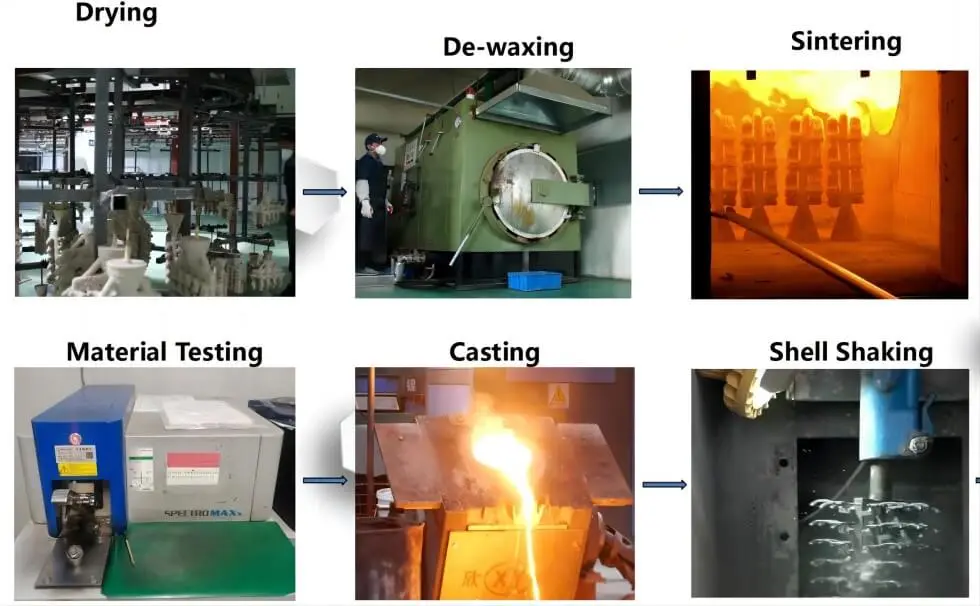

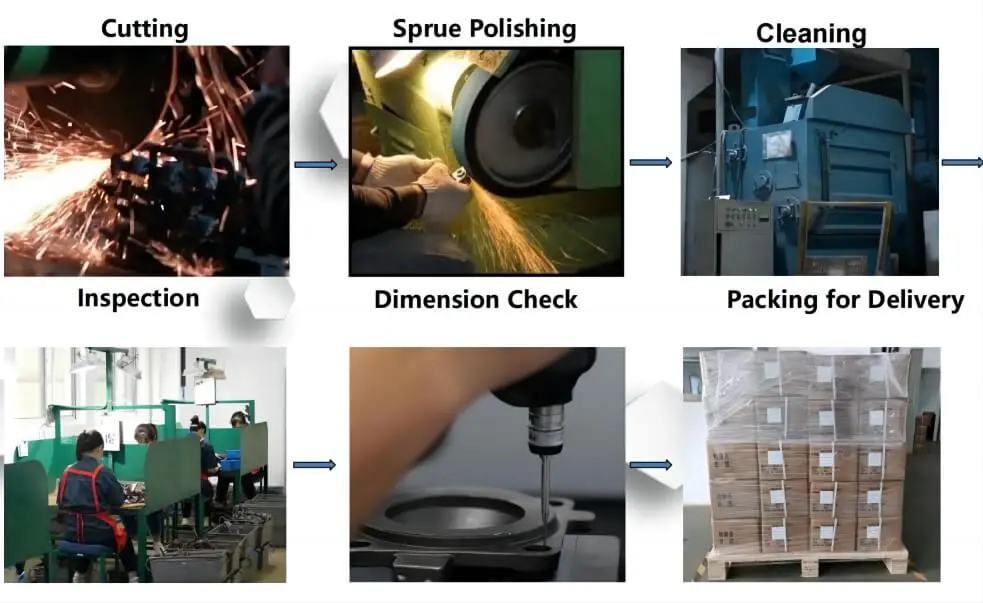

How Does Precision Casting is Made?

Precision Casting is also known as "lost wax casting". First, it need design and process the mold according to the product requirements of the customer, press the wax material into the mold to form a product wax pattern, bond with the sprue cup and the runner wax pattern to form a lost wax casting tree, and coat the wax tree with multiple layers of refractory slurry and sand After the material is made into a shell, the wax in the shell is melted by heating, and then the molten metal is poured into the shell that has been roasted at a high temperature. After the molten metal is solidified and cooled, the required post-processing methods such as cutting and cleaning can be obtained. of castings. Compared with other casting processes: it is applicable to a wide range of materials, and the cast products have complex structures, high surface roughness, and high dimensional accuracy, and can be processed with little or no processing. It is an advanced process of near-net shape.