The Ultimate Guide to Tool Steel Casting: Everything You Need to Know

Welcome to the ultimate guide to tool steel casting, where we delve into everything you need to know about this essential process. Tool steel casting plays a critical role in various industries, from automotive and aerospace to manufacturing and construction. In this comprehensive guide, we will walk you through the ins and outs of tool steel casting, covering its definition, advantages, applications, and top considerations. Whether you are a seasoned professional or new to the field, we have you covered. Discover the different types of tool steel, their unique properties, and which ones are best suited for specific applications. Learn about the casting techniques involved, including sand casting, investment casting, and die casting, and understand the benefits and limitations of each method. With our step-by-step guide, you will gain valuable insights into the tool steel casting process, from design and mold creation to melting, pouring, and finishing. We will also address common challenges and provide expert tips to help you achieve optimal results. So, whether you are seeking to enhance your knowledge or looking to implement tool steel casting in your operations, this guide is your go-to resource for all things tool steel casting. Let's dive in and unlock the potential of this versatile manufacturing technique.

Tool steel casting refers to the process of manufacturing components or parts using tool steel through the casting method. Tool steel is a type of high-carbon and high-alloy steel specifically designed for manufacturing tools, dies, and molds. It is known for its excellent hardness, wear resistance, toughness, and heat resistance.

Advantages of Tool Steel Castings

1,Hardness: Tool steel is characterized by its high hardness, allowing it to withstand heavy-duty applications and resist deformation under high stress.

2,Wear resistance: Tool steel exhibits exceptional wear resistance, making it suitable for tooling applications that involve cutting, machining, and forming operations.

3,Toughness: Tool steel possesses good toughness, which enables it to withstand impact and shock loads without fracturing.

4,Heat resistance: Tool steel can retain its hardness and strength at elevated temperatures, making it suitable for applications involving high temperatures, such as hot forging and die casting.

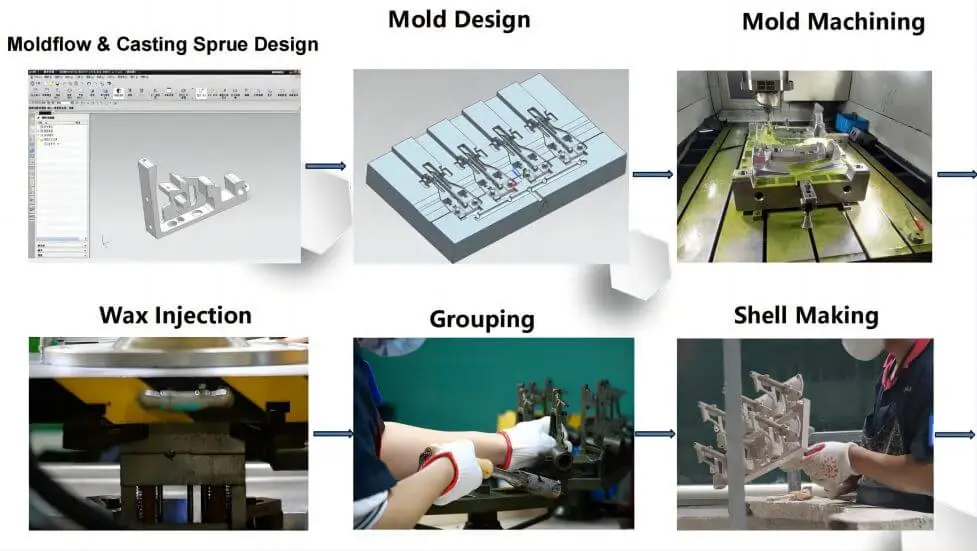

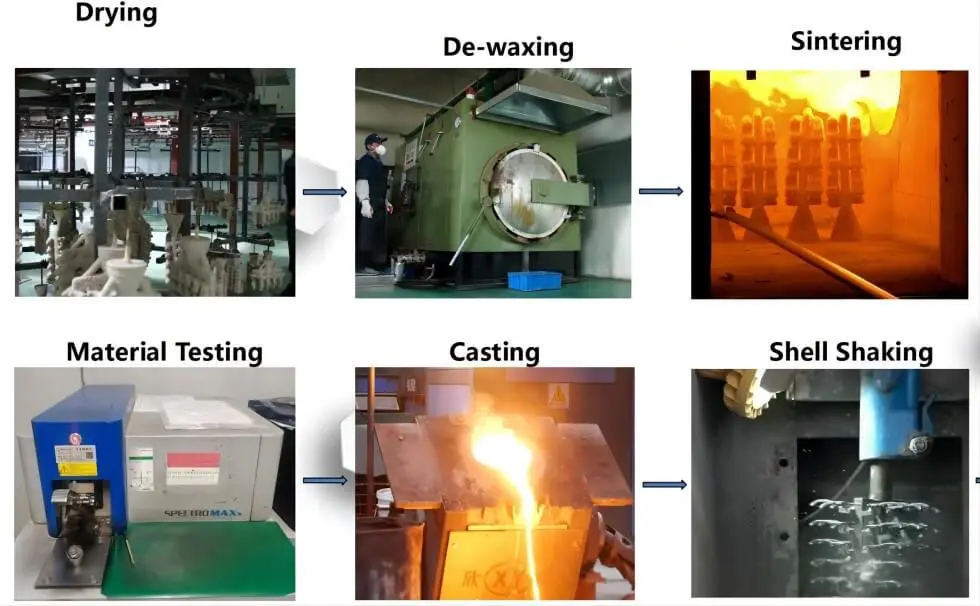

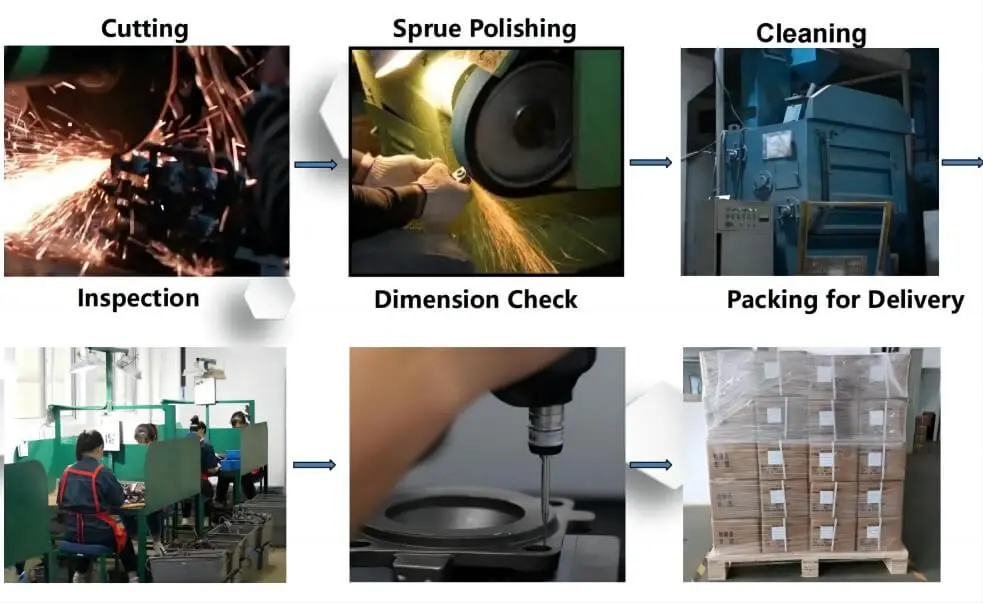

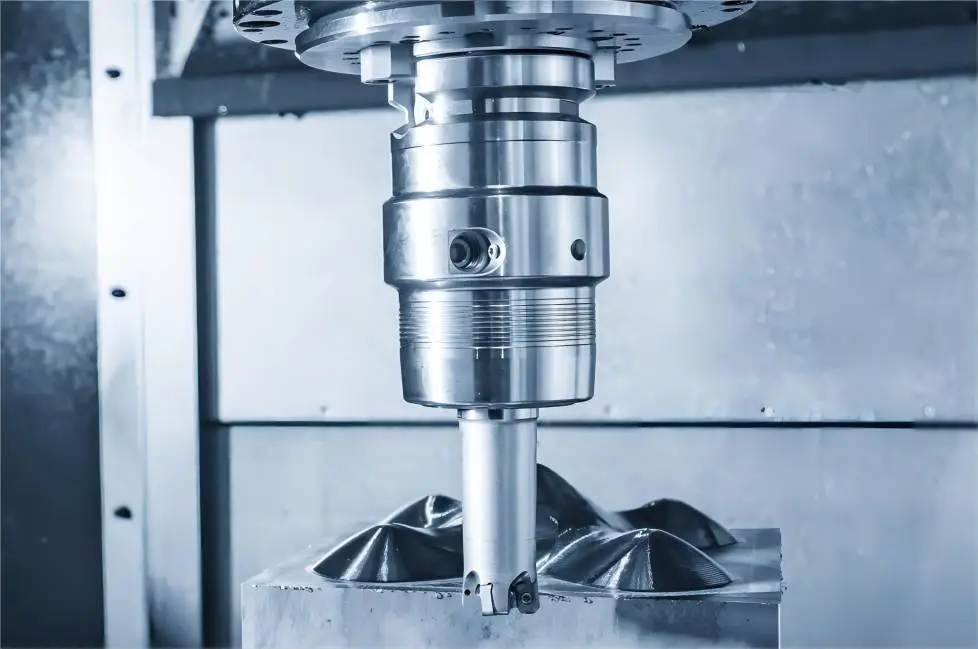

Tool steel casting involves melting the tool steel in a furnace and pouring it into molds or dies. Once the molten metal solidifies, it is removed from the mold, and post-processing steps like heat treatment, machining, and surface finishing may be performed to achieve the desired dimensions, properties, and surface quality.

Tool Steel Casting Process

Application of Tool Steel Casting in Manufacturing

Tool steel castings are widely used in various industries, including automotive, aerospace, construction, manufacturing, and tooling. They are utilized in the production of cutting tools, dies, molds, punches, inserts, and other components that require high strength, hardness, and wear resistance to withstand demanding applications.

1. Cutting Tools: process tools, milling cutters, turning tools, drill bits, etc. Tool steel has high hardness and wear resistance, which can maintain the sharpness and high efficiency of the cutting edge during the cutting process, and improve the cutting quality and production efficiency.

2. Stamping Dies: Stamping dies widely used in sheet metal processing need to have high strength and hardness, as well as good wear resistance and fatigue resistance. High version tool steel and cold work die steel are ideal materials for stamping dies.

3. Cold Extrusion Dies: Cold extrusion dies play a vital role in the metal forming process. Cold extrusion dies need to have high hardness, strength and wear resistance, and be able to maintain stable shape and precision under high pressure. Tungsten steel is a common material for cold extrusion dies.

4. Casting Mold: The casting mold needs to have high temperature resistance and wear resistance, and be able to withstand the erosion and high temperature erosion during the casting process. Suitable chrome steels and steel alloys are ideal materials for casting molds.

The Importance of Tool Steel Castings in Various Industries

From Concept to Creation: How Tool Steel Castings Shape Industries In today's fast-paced world, innovation and efficiency are key. And when it comes to shaping industries, tool steel castings play a crucial role. From automotive to aerospace, construction to manufacturing, these versatile and durable components are the backbone of modern innovation. At Lida Steel Foundry, we understand the importance of tool steel castings in shaping industries. Our commitment to quality and precision sets us apart as industry leaders in providing top-notch tool steel castings. Our skilled technicians and state-of-the-art facilities ensure that every casting meets the highest standards of strength, durability, and performance. By employing the finest materials and advanced manufacturing techniques, we create tool steel castings that can withstand extreme conditions while delivering unparalleled performance. Our castings are meticulously crafted to exact specifications, ensuring seamless integration into any application. With our expertise, we help businesses transform concepts into reality and drive advancements in various sectors.

Whether you're in need of a complex tooling solution or a simple component, our team at Lida Steel Foundry has the expertise and resources to deliver. Join us as we explore the world of tool steel castings and how they shape industries.