What are The Effects of The Melting Process of Stainless Steel Precision Casting?

The melting process of stainless steel precision casting is an important factor affecting the function of stainless steel precision casting. Because the smelting process directly determines the purity of the molten steel, it ultimately determines the connotation quality of the casting and the casting composition. The most important thing in the smelting process is to decarbonize and preserve chromium, followed by removing non-metallic inclusions in the molten steel as much as possible, and the carbon content is directly related to the function of the steel. The presence of carbon causes the grain boundary chromium deficiency of stainless steel to simply occur when welding or heating at about 510~788 ° C, resulting in intergranular corrosion.

Therefore, the corrosion resistance of stainless steel is strongly affected by the carbon content of steel. Low carbon (≤0.08%C) and ultra-low carbon (≤0.03%C) stainless steel is the development direction of modern stainless steel. This is stainless steel ingot supplied by steel mills with standard ingredients, and the foundry uses high-power induction furnace remelting method to produce. This is a simple and practical process for producing stainless steel precision casting.

Especially suitable for the large number of stainless steel precision casting manufacturers in China and the status quo of small scale, but because the commercialization of casting raw materials in our country is not perfect, this process method has not been well applied and developed in our country at present. This approach has broad prospects for development in our country. This process can produce 3041, 316 workpieces. However, this method is not suitable for the casting of nitrogen-containing stainless steel, and it is better to use the castings produced in this way.

Industrial pure iron and low carbon iron alloy are used as the material, after appropriate ratio, the composition is remelted and adjusted in the induction furnace. This process can greatly reduce the loss of chromium oxidation caused by oxygen blowing exercise, and the process is relatively simple. This method is only a remelting process, which can not remove various inclusions in the liquid steel due to raw materials, return charge or new occurrence in the melting process, so the purity of the charge is required to be higher.

In some small factories in China, this method is mostly used to produce stainless steel precision casting, and this method is mostly used to produce castings. This method of producing stainless steel precision casting can be used for occasions. In the electric arc furnace, through oxygen blowing and decarburization refining, most of the non-metallic inclusions in the molten steel can be removed, and the relatively pure stainless steel liquid can be removed. Oxygen blowing process is a process of carbon oxygen competition oxidation, in order to reduce the oxidation of chromium, carbon first oxidation, improve the oxygen blowing temperature to more than 1650℃.

With the decrease of carbon content in molten steel, the problem of chromium oxidation is becoming more and more serious. Therefore, the large loss of chromium oxidation and the difficulty in reducing the carbon content of molten steel to a very low level is a problem of this process. This process is suitable for producing stainless steel with a carbon content of about 0.1%, and it is difficult to produce low-carbon stainless steel with a carbon content of less than 0.05%.

The waste stainless steel was recovered and remelted by induction furnace. Scrap remelting equipment investment is small, the production process is simple, the cost of raw materials is low. However, the composition of the liquid steel in this way is difficult and the quality of the liquid steel is not high. The stainless steel castings produced by this method have higher carbon content, more inclusions in metallographic arrangement, black spots and oxidized rust spots on the surface of the castings, and low casting capacity. The scrap remelting method is applied in the simple foundry in China.

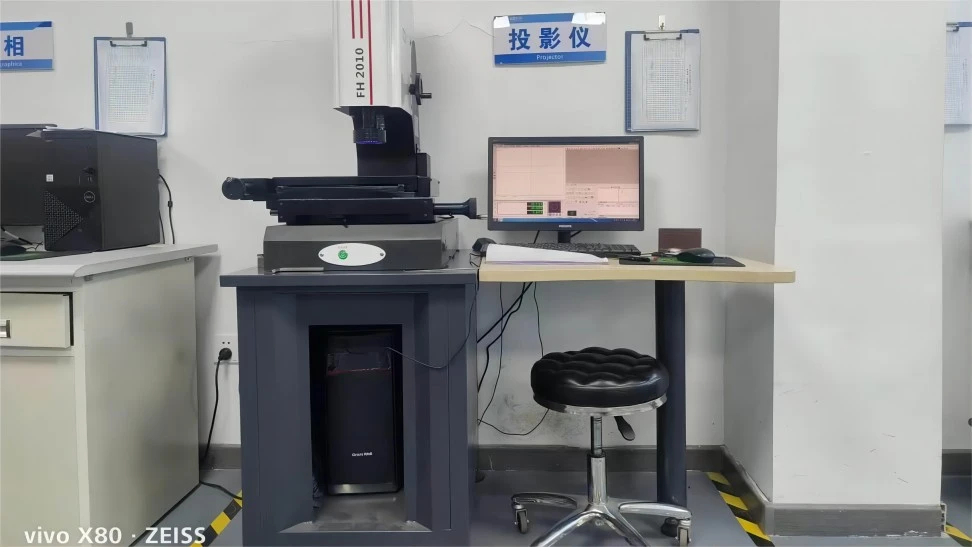

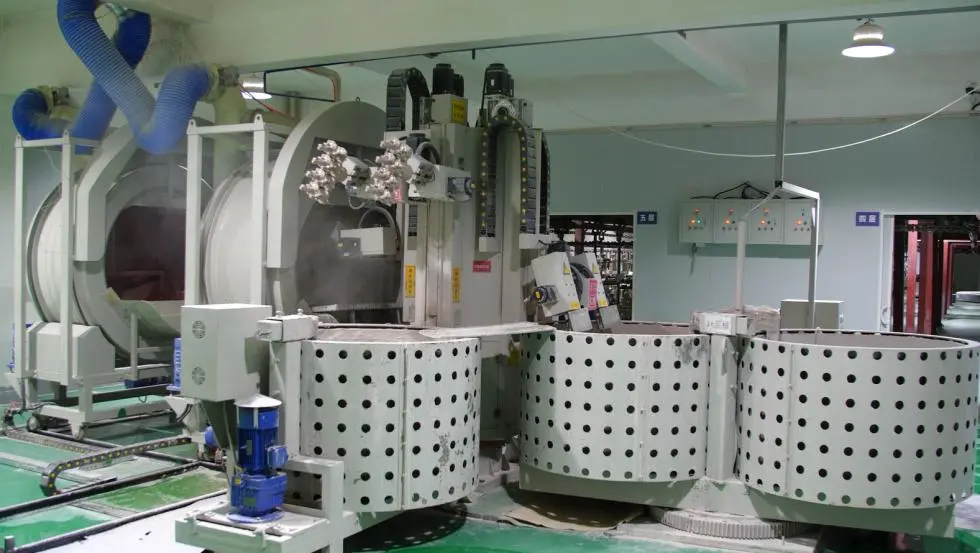

At Lida Steel Foundry, with decades of experience in precision casting industry, we understand the importance and difficulities of stainless steel precision casting in each production process. Our experienced technicians and well-trained workers pay close attention to every details that may affect the quality of final finished products. With the aid of the state-of-the-art facilities and our dedicated skilled teams, our commitment to quality and precision sets us apart as industry leaders in providing top-notch stainless steel precision castings. Our only aim is to ensure that every casting meets the highest standards of strength, durability, and performance.

Whether you're in need of a complex tooling solution or a simple component, our team at Lida Steel Foundry has the expertise and resources to deliver. Join us as we explore the world of stainless steel precision casting and how they contribute to our daily life.